CLT-1500-3 DTF Powder Shaker & Dryer | Professional DTF Shaker System

The CLT-1500-3 integrates automated powder application, segmented curing, and smoke purification into a single industrial unit. Designed for 650mm PET film workflows, it ensures Grade 4+ wash fastness with precise thermal control.

Key Features:

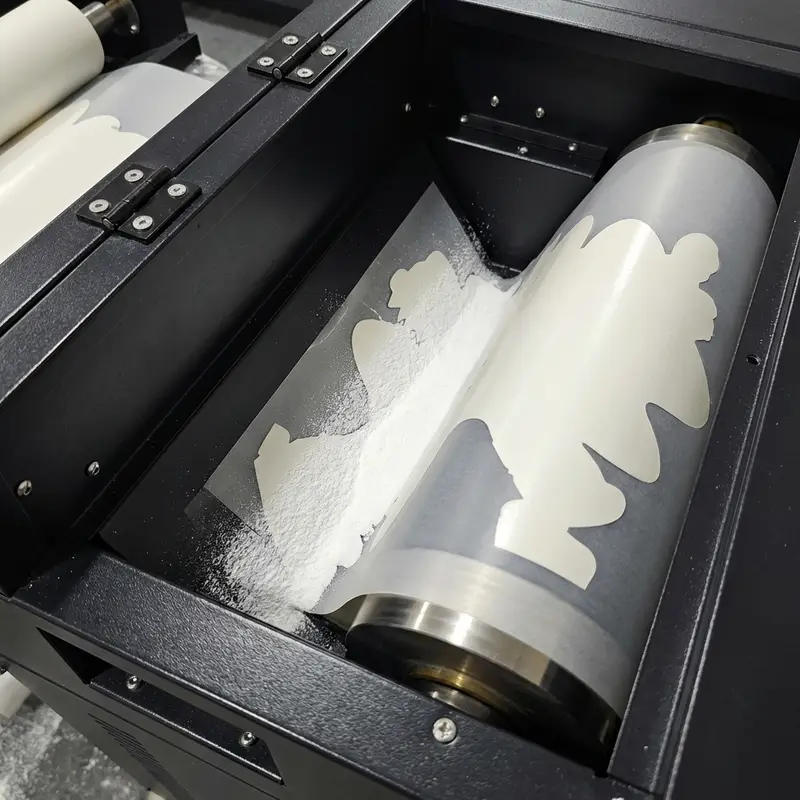

CLT-1500-3 Industrial Powder Shaker & Purifier | Integrated Curing Solution

The CLT-1500-3 is built for stability. Unlike standard shakers, it features a 2880mm extended mesh belt and a dual-zone heating chamber that stabilizes curing temperatures at exactly 140°C. This eliminates 'oily' returns on PET film and ensures consistent polymer melting across the full 650mm width. By integrating smoke purification, we eliminate external filtration needs, ensuring reliable performance under 24/7 load conditions.

Technical Metrics | CLT-1500-3 Industrial DTF Shaker

Field-ready technical metrics for the CLT-1500-3 system. The chassis is reinforced to maintain a mechanical tolerance of ±0.015mm, critical for long-run alignment. We also address industrial compliance: the integrated smoke purification unit captures 99% of curing fumes, meeting strict workshop air quality standards. Dual-zone heating is calibrated for 15-30°C environments.

Product Specifications

DTF Powder & Curing Process: Industrial Implementation

The CLT-1500-3 integrated powder shaking and curing workflow is optimized for industrial efficiency. Follow these protocols to maintain high-fidelity output and ensure Grade 4+ wash fastness on apparel transfers.

1. Asset Preparation

Prepare high-resolution assets suitable for 650mm film width. Note: Optimize nesting layouts to maximize film utilization during continuous production runs.

2. Integrated Printing

Initiate the print sequence on the connected DTF printer. The system deposits ink onto the PET film, which is then automatically fed into the shaker unit.

3. Powder & Curing

The unit applies TPU powder via the integrated shaker with sensors regulating coverage. Note: The built-in smoke purifier ensures a clean environment during this phase.

4. Curing Tunnel

Film passes through the 2880mm segmented heating tunnel. Important: Precise temperature control at 140°C ensures optimal polymer fusion without film deformation.

5. Heat Transfer Application

Apply heat (160-170°C) for 15-20 seconds to fuse transfers. Important: Use professional heat presses to match the industrial system's output quality.

6. Film Release

Remove PET film at a 45° angle post-cooling. Note: The integrated cooling fans accelerate this step, enabling immediate finishing.

Industry Applications | CLT-1500-3 System Implementation

The CLT-1500-3 integrated powder shaker is the definitive solution for high-volume textile customization. We provide the curing accuracy required for industrial garment production.

Custom Headwear

Custom headwear demands durable transfers that withstand curvature. The CLT-1500-3 produces high-elasticity transfers perfect for caps, ensuring logos remain crack-free.

Tote & Bag Customization

For canvas and synthetic bags, adhesion strength is paramount. Our curing process guarantees that transfers endure heavy daily use and abrasion without peeling.

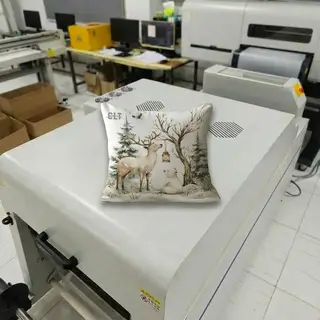

Customized Home Textiles

Home decor textiles require a soft hand feel. The precise powder melting control preserves the fabric's natural texture while delivering vibrant decorative prints.

Apparel Customization Shops

Apparel production requires Grade 4+ wash fastness. This system delivers consistent curing results, ensuring t-shirts maintain their visual appeal after repeated washing.