CLT-6900-6

The CLT-6900-6 is an industrial 6-head 9-color DTF printing machine featuring wide gamut output and 25 m²/h production speeds. The ultimate high-fidelity dtf machine for commercial apparel.

The CLT-012R is designed for high-quality mass production, which redefines industry standards with its exceptional performance.

The CLT-6900-6 is an industrial 6-head 9-color DTF printing machine featuring wide gamut output and 25 m²/h production speeds. The ultimate high-fidelity dtf machine for commercial apparel.

Premium CLT 1799V dtf printing ink engineered for Epson i3200 heads. Delivers high color density, superior fluidity, and stable performance for industrial dtf printer ink systems.

Industrial CLT-6900-5 system with 5 Epson I3200 heads. Achieve 30 m²/h throughput with this high-speed industrial dtf printer for large-scale apparel manufacturing.

High-speed DTF printer with white ink system. CLT-6900 delivers 1800 DPI precision and Grade 4+ wash fastness. Professional direct to film printing for custom apparel on cotton, nylon, and blends.

The CLT-6900-4 is a commercial DTF printing machine with fluorescent capability. Features 4 Epson I3200 printheads and 14 m²/h production speed for high-volume textile decoration.

Premium CLT 1798-3 dtf white ink optimized for Epson i3200 printheads. High opacity, superior fluidity, and excellent wash fastness for professional garment printing.

Industrial CLT-DTG-001 professional DTG printer for high-volume garment production. Features 4 Epson i3200 heads for CMYKORGB+W output with 1800 dpi precision.

High-quality CLT 1699V dtg color ink engineered for Epson i3200/i1600 heads. Delivers vibrant CMYK colors and superior fluidity for industrial direct to garment pigment ink systems.

Premium 1698-1 dtg white ink engineered for Epson printheads. Features high color density, superior covering power, and soft hand-feel for professional direct to garment ink systems.

Contact us today for a free consultation and quote.

DTF (Direct to Film) printing is a technology engineered to reproduce designs with high definition and excellent fastness on variable textiles.

Before starting DTF (Direct-to-Film) printing, you need to create your design through professional graphic design software.

The design is typically mirrored and CMYK inks are printed on the PET film, followed by white inks to create an opaque backing.

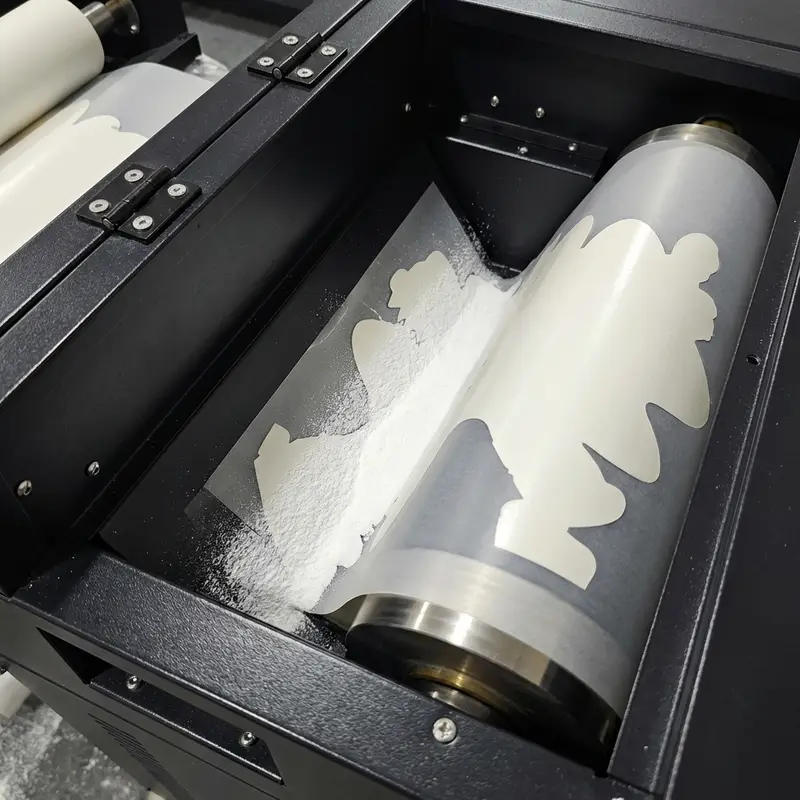

The hot-melt adhesive powder is applied to the printed areas while the inks remain tacky. And then the film is conveyed through a dryer. The powder is fused and then cured, therefore forming a flexible film on the surface.

The target fabric is placed on the platen of a heat press, and the cured PET film is put onto the fabric, applying a positioning system to ensure precise alignment for the final design.

The controlled temperature, pressure and time are applied to activate the powder and bond the printed patterns to the fabric fibers. This step is critical as it determines the adhesion strength and wash fastness of the transferred patterns.

The last step is to peel off the PET film after the heat-press process.

Are you curious about DTG printing? How does it turn the digital artwork into wearable art with exceptional precision, vibrancy and durability? Following steps will demystify the technology.

Before starting DTG printing, it is critical to design the pattern through professional graphic design software.

It is an essential step to prepare for DTG printing. The specialized pre-treatment solution allows DTG inks to firmly bond with the garment fibers, therefore enhancing print quality and preventing color fading after several washes.

Pre-curing can ensure an even and stable surface of pre-treatment solution, in order to realize high-definition DTG printing. Moreover, a heat press conduces to completing the process.

The fabric is put onto the platen of a DTG printer where the actual digital printing begins. For dark fabric, the white ink is firstly applied as the base layer to cover the original color of the substrate. And then CMYK inks are jetted directly onto the fabric.

The printed garment needs to be cured by a dryer after printed inks, which conduces to bonding the inks permanently to the fabric and ensuring long-lasting print quality.

Here is the printed garment with beautiful and vivid patterns.

Contact us today for a free consultation and quote.

Got an idea that’s ready to break out? We’re here to bring it to life—vivid and real. Our mission goes far beyond offering chemicals. We collaborate with you to transform your core concept into tangible success. So once you have a good idea, we have advanced chemicals and equipment to make it come true. Let’s create something incredible together!

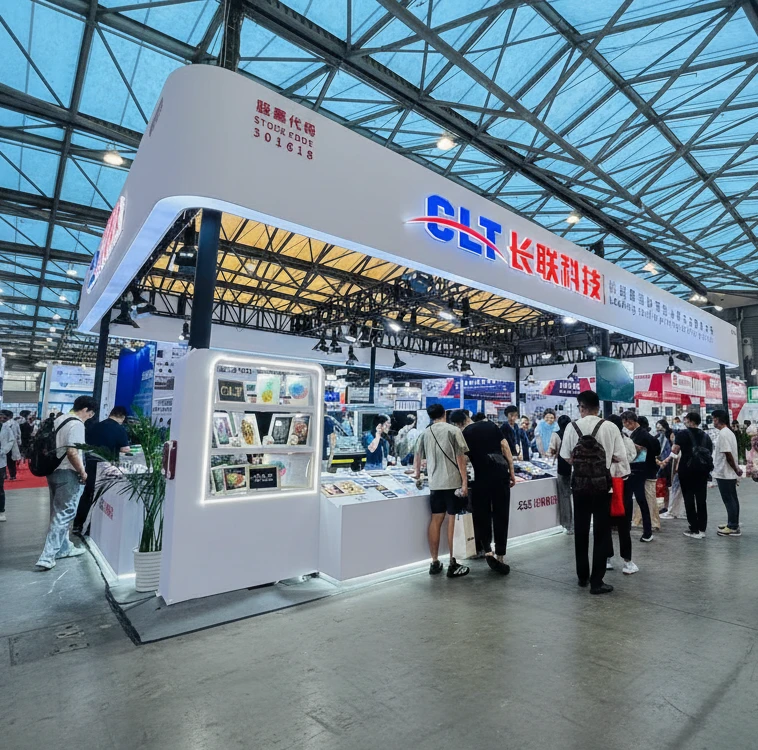

After years of commitment to innovation, CLT has been listed on the Shenzhen Stock Exchange’s ChiNext Board. This milestone marks the commencing of a new chapter for its growth and the textile printing sector.

Hear real reviews from our global customers and see how CLT's printing solutions help them achieve their goals.

As a leading textile printing solutions provider in China, CLT proactively participates in trade fairs and exhibitions around the world that are devoted to screen printing, DTG printing, and DTF printing. Our presence at global events serves as a bridge to connect with other brands, partners and counterparts. Find us at international fairs and exhibitions to experience our printing solutions and discuss how we can bring your designs to life.

Here are the most frequently asked questions from customers. If you have other questions, please feel free to contact us.

Yes. Our professional technical team provides comprehensive support. After you buy our machines, we will dispatch technicians to your company for on-site training. The training will continue until your operators are fully proficient. Additionally, our technicians are available for ongoing online guidance.

12 months.

Quality: We maintain strict control on quality by manufacturing the majority of components in-house at our advanced facilities. Every piece of equipment is assembled and tested before delivered to our customers, to ensure superior performance and durability. Service & Support: Your investment is supported by a comprehensive global network. We provide professional technical training, 24/7 consultation services, and warmhearted after-sales services. Furthermore, by leveraging the wide range of products from CLT, we offer unparalleled long-term solutions to help your company attract ever-growing customers.

The print speed depends on the number of printheads. Let me take DTF Printers, CLT-6900-4 and CLT-6900-6, as an example. CLT-6900-4 has 4 printheads and CLT-6900-6 has 6 printheads. The print speed is 14 m²/h (4 PASS) and 25m²/h (4 PASS) respectively.

The prints offer excellent wash fastness, provided that high-quality holt melt adhesive powders are used and all application guidelines are followed correctly. Our internal test method is that we applied detergent to wash printed fabrics at 60℃ for 12.5 hours. There is no blocking or fractures on the printed area after washing.

Firstly, the machine is professionally disassembled (if needed), crated and packaged to withstand long-term shipping. Secondly, we typically ship it via a reliable carrier for cost-effectiveness on larger shipments. The best option will be confirmed based on your location and requirements. Lastly, the machine is delivered to the nearest port in your country or region.

The delivery time is typically one month for equipment and 7 days for chemicals, respectively.

We are a comprehensive textile printing solutions provider producing both chemicals and equipment.