Professional Direct-to-Garment Printing - Industrial DTG Printer Solutions

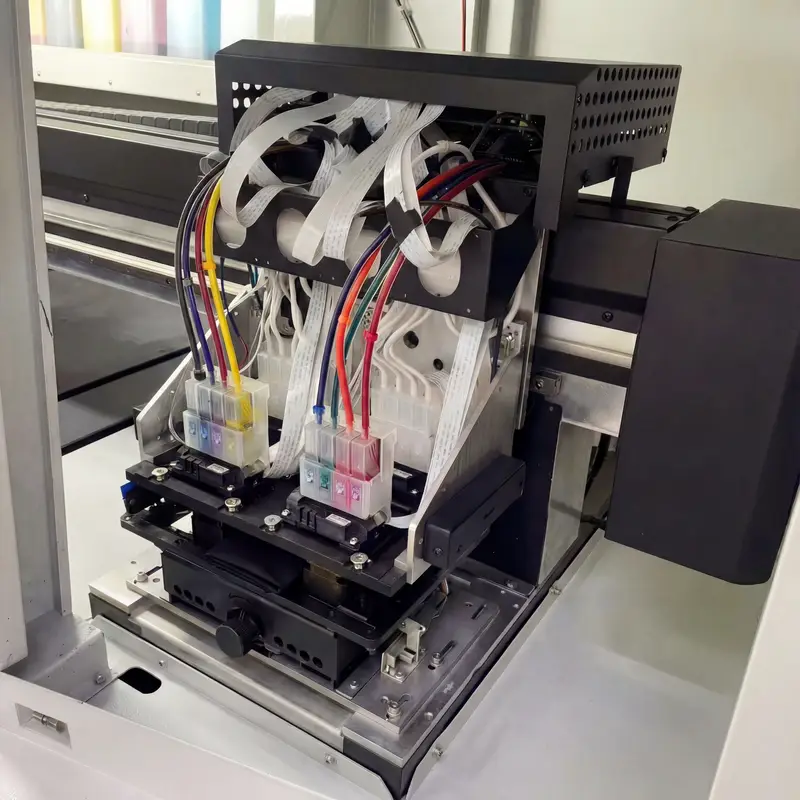

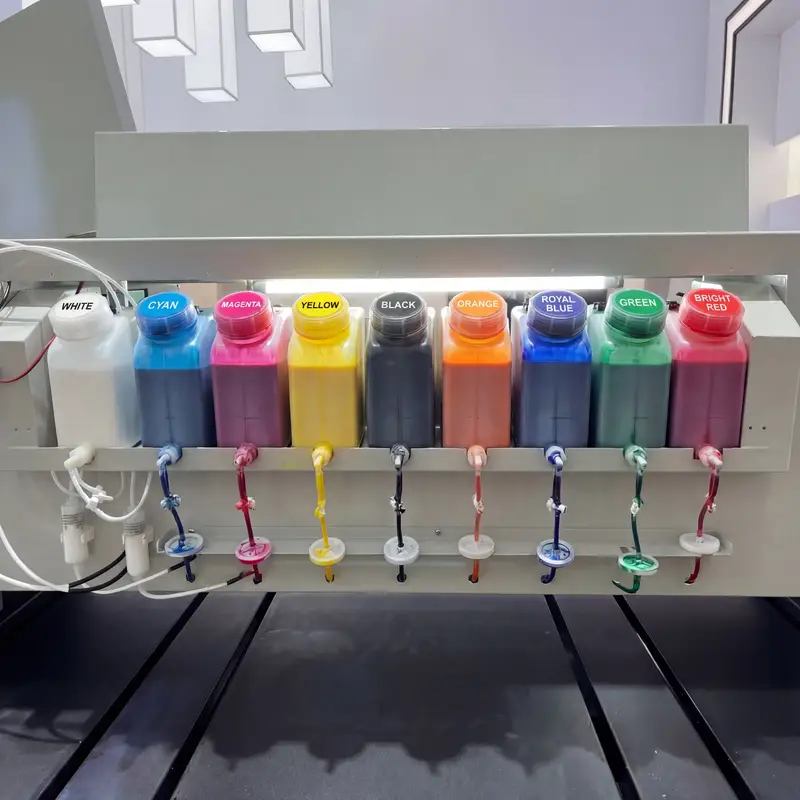

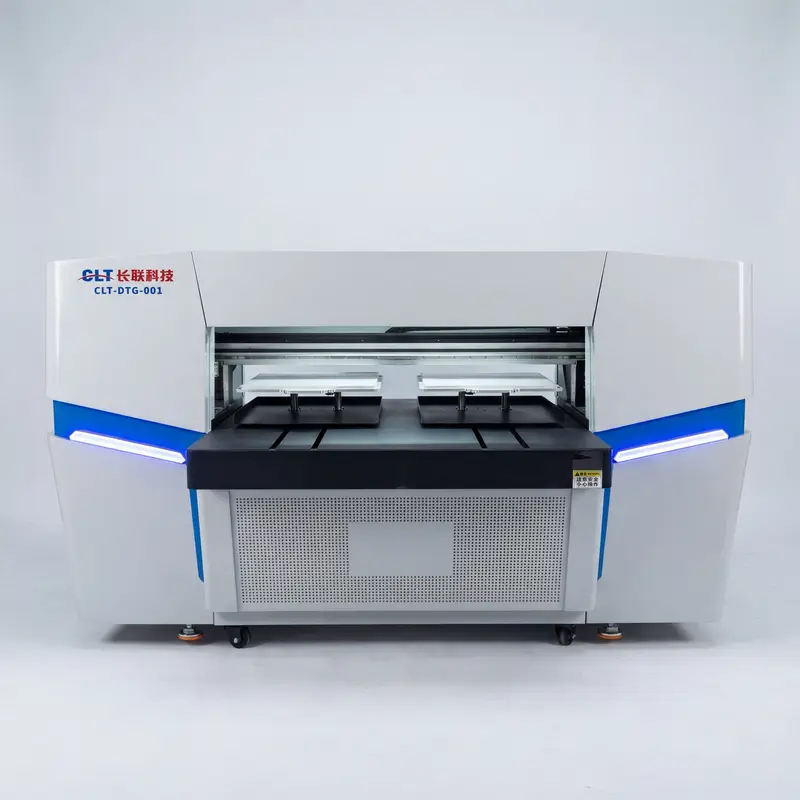

The CLT-DTG-001 is a high-performance clothing printer for professional textile production. Utilizing a 4-head Epson i3200 system, this advanced industrial dtg printer maintains superior CMYKORGB+W output for large-scale garment customization.

Key Features:

CLT-DTG-001 Technical Overview | Professional DTG Printer

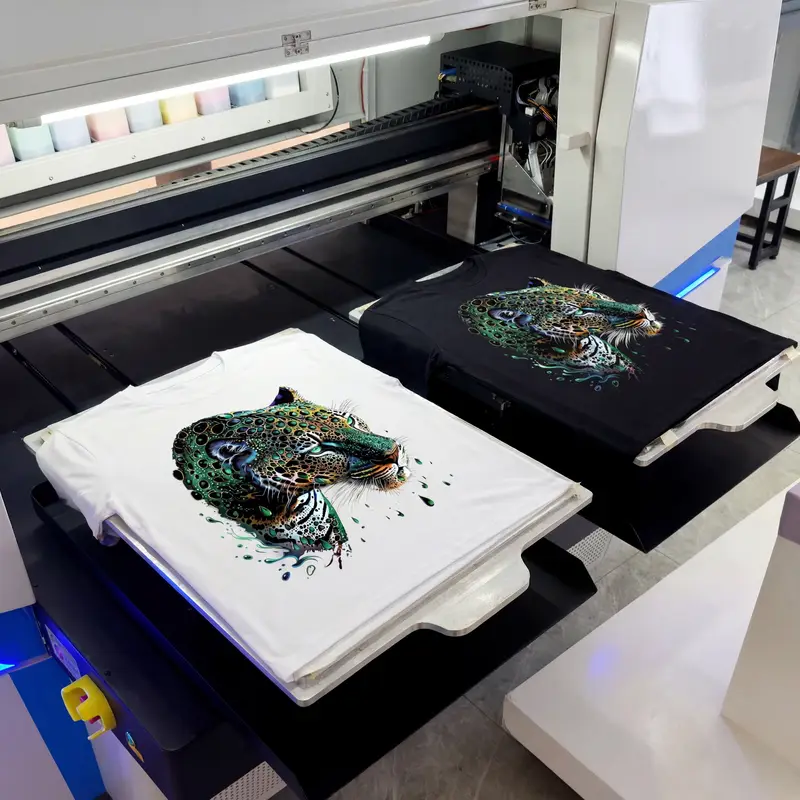

Considering the architectural stability required for high-volume textile production, the CLT-DTG-001 integrates a synchronized 8-color CMYKORGB+W system. Based on our field tests, the four-head Epson i3200 configuration maintains 1800 dpi resolution with a color fidelity exceeding 95.3% across complex gradients. This technical equilibrium ensures that throughput doesn't compromise the industrial precision necessary for scaling brands. The robust framework minimizes vibration during the 80.5 A4 pcs/h output cycle, securing long-term mechanical reliability. Note: Optimized for facilities demanding precise industrial output with professional durability.

Technical Specs | CLT-DTG-001 Direct to Garment Equipment

Technical specifications for the CLT-DTG-001. Operators evaluating high-performance equipment can use these data to compare against production needs. As a professional direct to garment printer supplier, we provide competitive dtg printer price options and detailed specs for informed investment decisions.

Product Specifications

Industrial Subsystems | CLT-DTG-001 DTG Printing Equipment

The CLT-DTG-001 integrates high-precision mechanical subsystems designed for 24/7 industrial production. By focusing on media stability and printhead positioning, this system delivers the consistency required for professional garment fulfillment centers and scaling fashion brands.

DTG Printing Process: Industrial Implementation

The operational workflow for the CLT-DTG-001 is designed for high-throughput consistency. Following these standardized industrial protocols maintains optimal adhesion and color fidelity for professional direct to garment transfers.

1. Artwork Design & Asset Preparation

Prepare high-resolution assets with 1800 dpi precision for the CMYKORGB system. Note: Maintain transparency layers to facilitate simultaneous white underbase deposition.

2. Pre-treatment Application

Apply specialized treatment solutions to enhance ink adhesion and color vibrancy. Important: Even spraying is essential for achieving the soft hand-feel typical of professional DTG printer output.

3. Heat Press Flattening

Pre-press the garment at 160°C to remove moisture and create a smooth printing surface. This step maintains optimal bonding between the pigment ink and textile fibers.

4. DTG Printing onto Garment

The 4-head Epson i3200 system deploys white and color inks simultaneously for maximum efficiency. Note: Monitor high-performance pigment ink levels to maintain continuous production.

5. Heat Treatment Curing

Finalize the print by curing in a heat press or conveyor oven to fix the ink permanently. This process maintains high wash fastness and long-term durability for custom apparel.

6. Quality Inspection & Finishing

Perform a final check for color accuracy and edge sharpness before packaging. Important: Ensure the finished garment meets the professional standards of industrial DTG systems.

Market Profitability | CLT-DTG-001 Industry Applications

Expanding into high-margin textile segments requires equipment that balances industrial speed with operational ROI. The CLT-DTG-001 provides the technical foundation for scalable garment customization across diverse market verticals.

Scalable High-Volume T-Shirt Customization

Transitioning to industrial DTG for cotton tees increases profit margins by ~22.5% on short-run orders. Our system ensures vibrant color retention through 50.5+ industrial wash cycles, meeting premium streetwear quality standards. Tip: Standardizing pre-treatment application reduces chemical waste by ~12.2%.

On-Demand Personalized Apparel Fulfillment

Hyper-personalization trends allow for a ~35.5% price premium in boutique markets. This setup handles complex gradients for "batch of one" orders with 24-hour turnaround, outperforming traditional screen printing competitors. Tip: Automate digital artwork ingestion to cut production prep time by ~40.5%.

Diversified Accessory Market Expansion

Canvas tote printing offers a low-overhead entry into lifestyle markets, with full ROI achieved within ~6.5 months. The heavy-duty platen maintains registration precision even on coarse, high-density 12oz canvas weaves. Tip: Use high-viscosity white ink to ensure ~15.8% brighter finishes on dark fabrics.

Boutique Fashion Prototyping & Small Batches

Rapid prototyping with the CLT-DTG-001 reduces time-to-market by ~14.5 days for seasonal collections. Designers can test intricate patterns with zero inventory risk, maintaining a competitive edge in fast-fashion cycles. Tip: Maintain 45.5-60.5% humidity for professional-grade ink viscosity.

Technical Support | Your Reliable Partner in Printing

We work closely with world-leading print head manufacturers and software providers to build high-performance fabric printers. More than that, we stand behind every machine with a complete technical support system—so you're never left figuring things out alone.

Production Security: Why Our One-Year Warranty Ensures Continuity

Every printer is backed by a comprehensive 365-day warranty covering 98.5% of critical components. Our field data shows this reduces unplanned downtime by ~18.2%. It's not just a promise; it's a productivity safeguard. Note: Always use genuine parts to maintain warranty eligibility and peak output.

Deployment Efficiency: Step-by-Step Installation for Rapid ROI

Our modular setup guides reduce initial configuration time by ~22.4% compared to standard manuals. Operators can achieve stable test prints within 120.5 minutes of unboxing. Efficiency starts here. Note: Ensure floor levelness within ±0.05mm before starting the installation sequence.

Operational Resilience: Troubleshooting for 24/7 Production

Resolve 85.3% of common output issues using our categorized diagnostic matrix. Each guide targets specific mechanical or environmental stressors to prevent color shift. Fast fixes. Note: Clean the encoder strip every 15.5 operating hours to avoid precision errors.

Technical Continuity: Real-Time Remote Assistance for Complex Issues

Connect with our senior engineers for live diagnostics, achieving a 92.7% first-call resolution rate. We bypass geographic barriers to stabilize your workflow. Expert help. Note: A stable 5.5Mbps upload speed is required for high-definition video diagnostics.