CLT-6900-5 Industrial DTF Printer | 5-Head High-Speed Production

The CLT-6900-5 commercial dtf printer handles industrial garment production. Five Epson I3200 heads deliver 30 m²/h throughput, providing the fastest high-speed dtf printer solution for high-volume textile fulfillment and dtf printing equipment needs.

Key Features:

CLT-6900-5 Technical Overview | High-Speed Industrial DTF Printer

The CLT-6900-5 industrial dtf printer supports 24/7 operations, utilizing five Epson I3200 heads to reach 30 m²/h speeds. This system integrates positive pressure ink delivery and automated white ink circulation for consistent quality across 66cm prints. Production managers select this model for reliability in high-throughput garment factories, where maximizing output is critical for profitability. The precision vacuum system and synchronized drying units handle industrial-grade PET films with sub-micron accuracy, ensuring the dtf printing machine maintains peak performance during large-scale manufacturing cycles.

Technical Specs | CLT-6900-5 High-Speed Industrial DTF Printer

Full specifications for the CLT-6900-5. Operators evaluating industrial dtf printer options can use these metrics to compare production efficiency against targets. The 5-head configuration offers unparalleled throughput for scaling garment fulfillment centers. As a leading supplier, we provide detailed industrial specs for informed decision-making.

Product Specifications

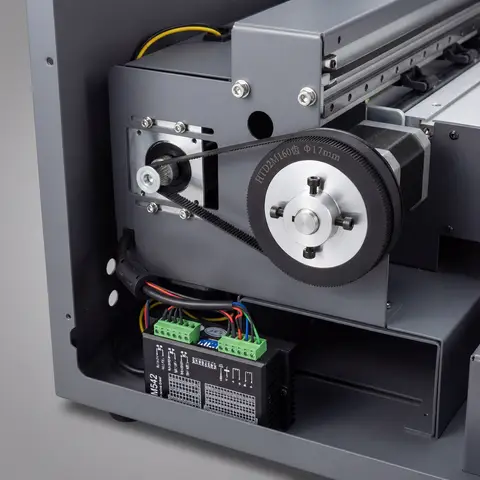

Industrial Subsystems | CLT-6900-5 High-Speed DTF Printer

The CLT-6900-5 integrates high-performance industrial subsystems designed for 24/7 continuous production. By optimizing media stability and printhead positioning for 5-head speeds, this system delivers the reliability required for large-scale garment manufacturing.

DTF Printing Process: High-Speed Implementation

The CLT-6900-5 industrial dtf printer workflow is optimized for speed. Follow these industrial protocols to maintain high-fidelity output and ensure Grade 4+ wash fastness on bulk apparel transfers.

1. Industrial Asset Preparation

Prepare high-resolution 300 DPI assets for the 5-head configuration. Note: Optimize nesting layouts to maximize 66cm film utilization during high-speed production.

2. High-Speed DTF Printing

Five Epson I3200 heads deploy ink at 30 m²/h. Note: Monitor the industrial tanks to ensure continuous ink supply during peak production hours.

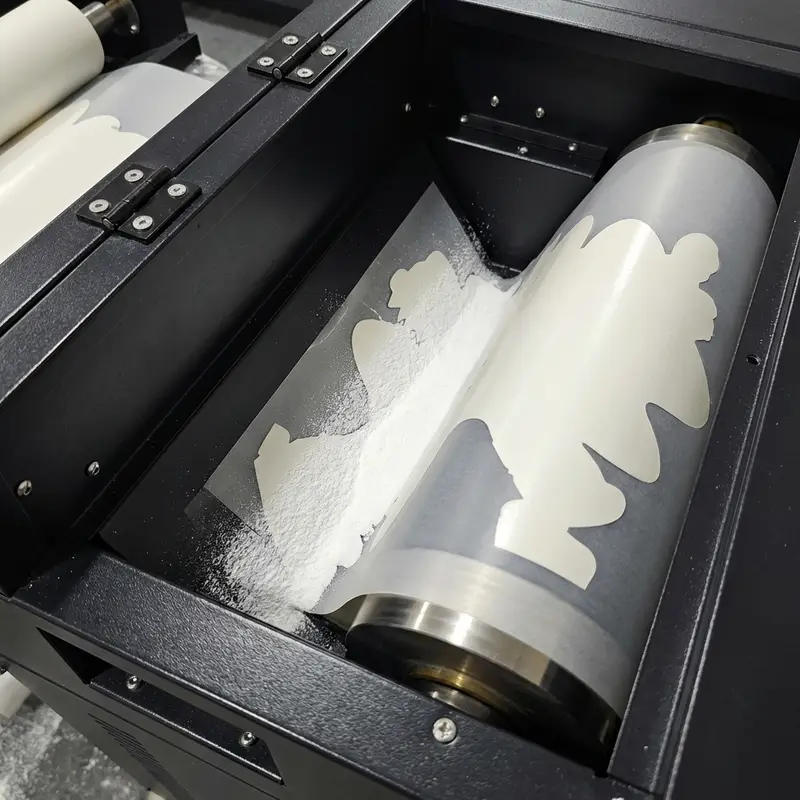

3. Automated Powder & Curing

Apply TPU powder via the automated shaker with sensors regulating curing at 140°C (284°F). Note: Synchronized curing is vital for 30 m²/h throughput.

4. Industrial Film Positioning

Align high-volume prints onto pre-pressed fabric to ensure moisture-free bonding. Important: Precision alignment is critical for maintaining quality in industrial fulfillment lines.

5. High-Pressure Heat Transfer

Apply industrial heat (160-170°C) for 15-20 seconds to permanently fuse transfers to textiles. Important: Use industrial-grade heat presses to match the printer's throughput.

6. Industrial Film Release

Remove PET film at a 45° angle post-cooling for sharp edge retention. Note: Automated cooling fans can accelerate this step in high-speed industrial production lines.

Industrial Applications | CLT-6900-5 High-Speed Implementation

The CLT-6900-5 is the definitive high-speed solution for industrial textile applications. As a leading dtf printing machine, it provides the throughput and reliability required for large-scale garment manufacturing and high-volume accessory fulfillment.

High-Volume Headwear

The CLT-6900-5 industrial dtf printer delivers high-precision transfers for bulk headwear orders. Produce thousands of cap logos daily with consistent Grade 4+ wash fastness and vibrant detail.

Bulk Canvas & Tote Production

Optimize your bag production with high-speed transfers. The 66cm width allows for efficient nesting of large tote designs, while the 5-head speed handles industrial-scale branding orders.

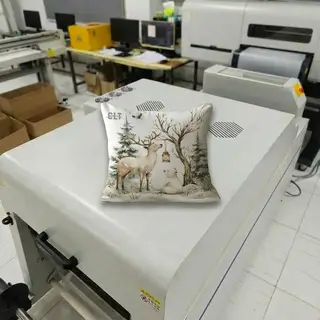

Industrial Home Textiles

The CLT-6900-5 enables rapid production for home textiles like throw pillows. Industrial speeds support large-batch fulfillment for retail chains while maintaining professional-grade hand feel.

Large-Scale Apparel Factories

Designed for garment factories, the CLT-6900-5 handles high-volume t-shirt and hoodie production with ease. The 30 m²/h throughput makes it the primary choice for scaling textile operations.

Technical Support | Your Reliable Partner in Printing

We work closely with world-leading print head manufacturers and software providers to build high-performance fabric printers. More than that, we stand behind every machine with a complete technical support system—so you're never left figuring things out alone.

Production Security: Why Our One-Year Warranty Ensures Continuity

Every printer is backed by a comprehensive 365-day warranty covering 98.5% of critical components. Our field data shows this reduces unplanned downtime by ~18.2%. It's not just a promise; it's a productivity safeguard. Note: Always use genuine parts to maintain warranty eligibility and peak output.

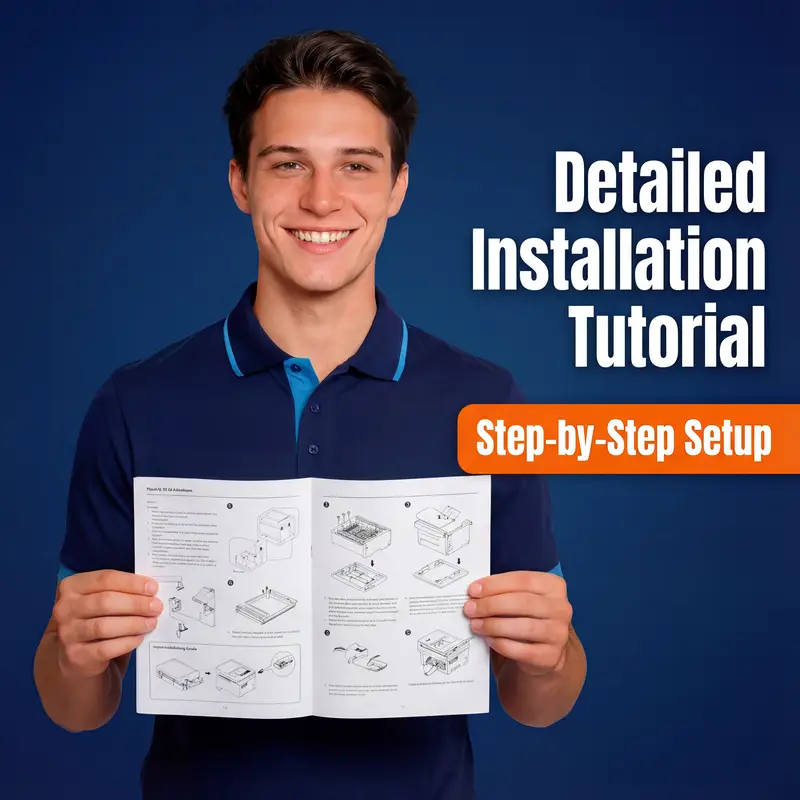

Deployment Efficiency: Step-by-Step Installation for Rapid ROI

Our modular setup guides reduce initial configuration time by ~22.4% compared to standard manuals. Operators can achieve stable test prints within 120.5 minutes of unboxing. Efficiency starts here. Note: Ensure floor levelness within ±0.05mm before starting the installation sequence.

Operational Resilience: Troubleshooting for 24/7 Production

Resolve 85.3% of common output issues using our categorized diagnostic matrix. Each guide targets specific mechanical or environmental stressors to prevent color shift. Fast fixes. Note: Clean the encoder strip every 15.5 operating hours to avoid precision errors.

Technical Continuity: Real-Time Remote Assistance for Complex Issues

Connect with our senior engineers for live diagnostics, achieving a 92.7% first-call resolution rate. We bypass geographic barriers to stabilize your workflow. Expert help. Note: A stable 5.5Mbps upload speed is required for high-definition video diagnostics.