CLT-6900-4 Fluorescent DTF Printing Machine | Commercial Epson I3200 System

The CLT-6900-4 is a DTF printer with fluorescent ink capability for commercial textile production. It uses 4 Epson I3200 printheads to support simultaneous CMYK, fluorescent, and white output. Production speeds reach 14 m²/h in 4-pass mode.

Key Features:

CLT-6900-4 DTF Printing Machine with Fluorescent Capability

The CLT-6900-4 is a DTF printing machine designed for commercial operations requiring fluorescent output. It uses 4 Epson I3200 printheads for simultaneous CMYK, fluorescent, and white ink printing. The fluorescent system produces vibrant designs visible under both normal and UV lighting. This makes the unit suitable for sportswear and promotional items requiring high visual impact. Note: Operating environment should maintain 15-25°C and 30-65% humidity. The three-section heating system requires approximately 10-15 minutes warm-up before production.

CLT-6900-4 DTF Printing Machine Technical Specifications

Technical specifications for the CLT-6900-4 commercial DTF printing machine. This system features Epson I3200 printheads and supports fluorescent ink output for professional textile decoration.

Product Specifications

CLT-6900-4 DTF Printing Machine Key Features

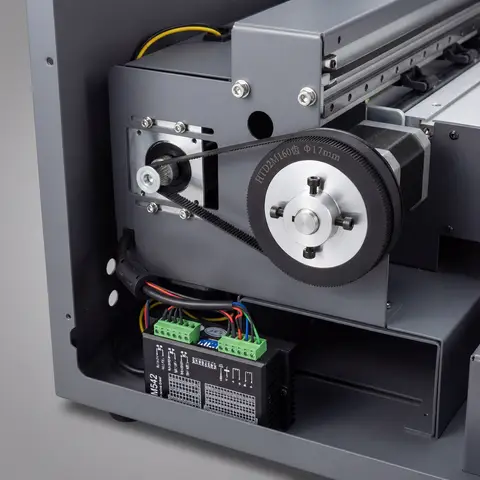

The CLT-6900-4 is a professional DTF printing machine with fluorescent capability. The system combines a 4-printhead configuration with advanced media handling for commercial output.

DTF Heat Transfer Process: Step-by-Step Guide

The DTF heat transfer process using this system typically takes 15-25 minutes per batch. The fluorescent ink capability adds visual impact without changing the basic workflow.

1. Artwork Design

Prepare artwork in Illustrator or CorelDRAW at 300 DPI minimum. Mirror the design before printing. Fluorescent channels require separate layer setup in the RIP software.

2. DTF Printing onto PET Film

The system applies CMYK, fluorescent, and white inks onto PET film. 4-printhead configuration allows simultaneous output, reducing print time to approximately 3-8 minutes.

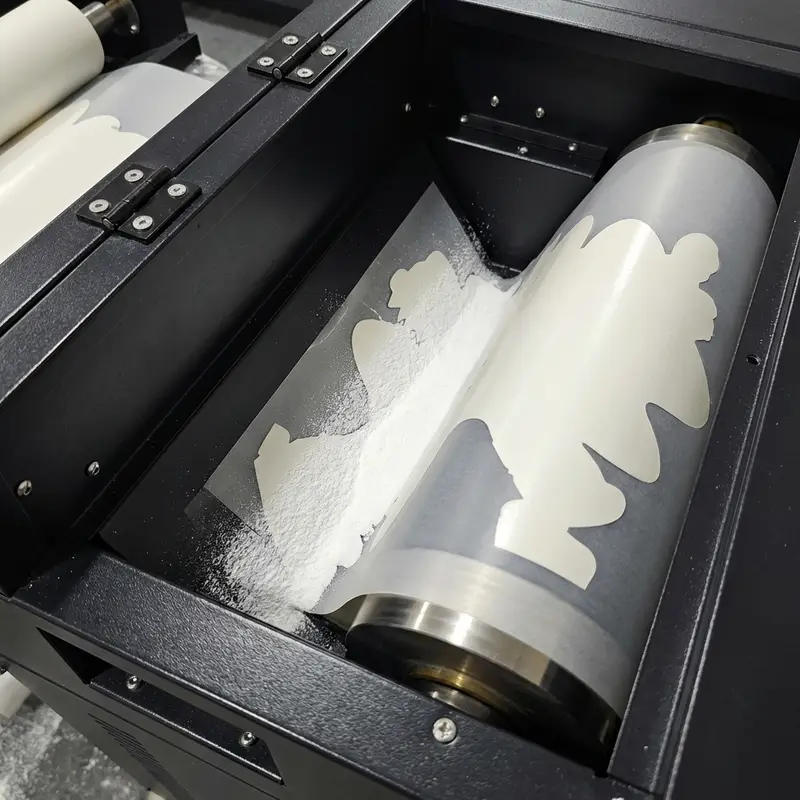

3. DTF Powder Application & Curing

TPU powder is applied to tacky ink. The film cures at 100-120°C for 2-3 minutes. The three-section heating system maintains consistent temperature across the curing zone.

4. Precision Film Positioning

Place garment on the heat press and position the cured PET film. Pre-press fabric for 3-5 seconds to remove moisture. Alignment marks help with placement accuracy.

5. DTF Heat Transfer Press Application

Settings for fluorescent transfers: 160-170°C, medium pressure, 15-20 seconds. This activates the adhesive for bonding. Important: Lower settings may affect wash fastness.

6. Film Release

Peel the PET film at a 45° angle after pressing. Fluorescent transfers typically use hot peel for faster throughput. Wait 5-10 seconds before removal for best results.

Commercial Applications | DTF Printing Machine Versatility

The CLT-6900-4 fluorescent DTF system supports various textile decoration applications with high durability and color impact.

Hats

DTF printing produces durable decoration on caps and hats. The fluorescent ink maintains color vibrancy through regular use. Note: Curved surfaces require careful positioning.

Bags

Apply designs to backpacks, totes, and promotional bags. The adhesive layer bonds securely to polyester and nylon substrates. Note: Test adhesion on coated fabrics before production.

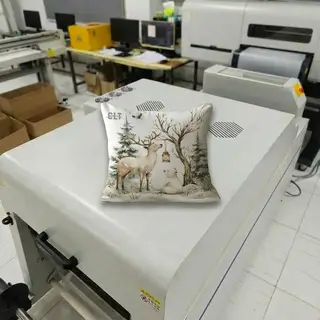

Throw Pillows

Create custom home decor with bright, fluorescent patterns. The prints maintain a soft hand feel and high wash fastness. Production typically requires 15-20 minutes per batch.

Clothes

Suitable for sportswear, safety apparel, and custom t-shirts. The 4-printhead system supports high-volume garment decoration. Most operators achieve proficiency within one business day.

Technical Support | Your Reliable Partner in Printing

We work closely with world-leading print head manufacturers and software providers to build high-performance fabric printers. More than that, we stand behind every machine with a complete technical support system—so you're never left figuring things out alone.

Production Security: Why Our One-Year Warranty Ensures Continuity

Every printer is backed by a comprehensive 365-day warranty covering 98.5% of critical components. Our field data shows this reduces unplanned downtime by ~18.2%. It's not just a promise; it's a productivity safeguard. Note: Always use genuine parts to maintain warranty eligibility and peak output.

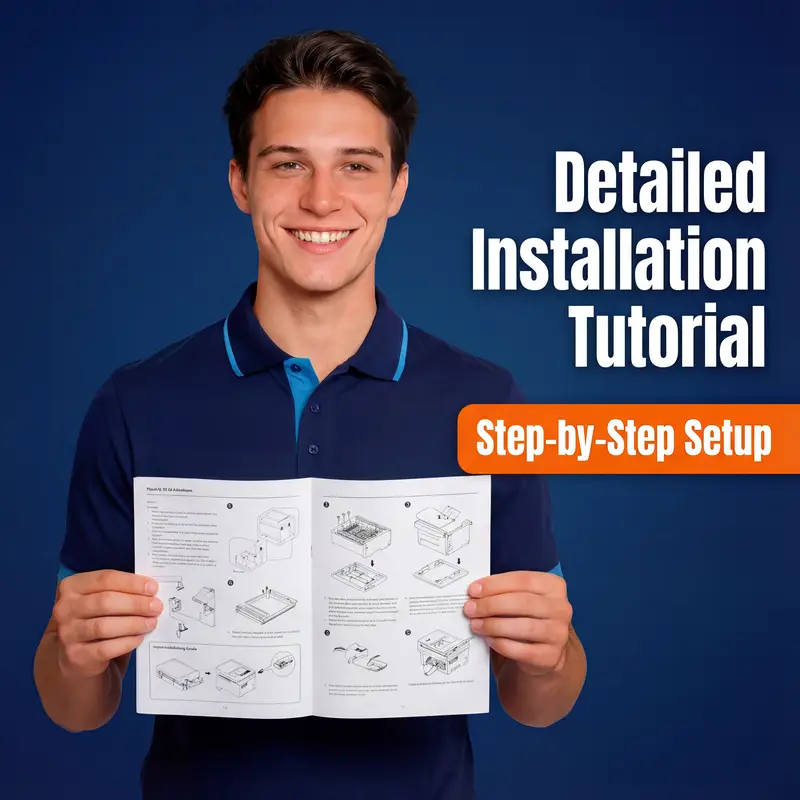

Deployment Efficiency: Step-by-Step Installation for Rapid ROI

Our modular setup guides reduce initial configuration time by ~22.4% compared to standard manuals. Operators can achieve stable test prints within 120.5 minutes of unboxing. Efficiency starts here. Note: Ensure floor levelness within ±0.05mm before starting the installation sequence.

Operational Resilience: Troubleshooting for 24/7 Production

Resolve 85.3% of common output issues using our categorized diagnostic matrix. Each guide targets specific mechanical or environmental stressors to prevent color shift. Fast fixes. Note: Clean the encoder strip every 15.5 operating hours to avoid precision errors.

Technical Continuity: Real-Time Remote Assistance for Complex Issues

Connect with our senior engineers for live diagnostics, achieving a 92.7% first-call resolution rate. We bypass geographic barriers to stabilize your workflow. Expert help. Note: A stable 5.5Mbps upload speed is required for high-definition video diagnostics.