CLT-6900-6 Industrial 9-Color DTF Printing Machine | 6-Head High-Fidelity

The CLT-6900-6 industrial DTF printer utilizes a sextuple Epson I3200 head configuration to achieve production speeds up to 25 m²/h. Operators benefit from an expanded 9-color gamut (CMYK+RGBOR+W), ensuring high-fidelity output for large-scale garment manufacturing. This commercial DTF printer is engineered for 24/7 stability in high-throughput environments.

Key Features:

Industrial High-Speed DTF Printing | 6-Head Efficiency

The CLT-6900-6 is a flagship industrial DTF printer designed for factories requiring maximum throughput and color accuracy. By integrating six Epson I3200 heads, the system maintains a stable 25 m²/h output without sacrificing detail. Operators can utilize the 9-color ink system to reproduce complex gradients and brand-specific colors that standard 4-color systems cannot match. Note: The peristaltic pump positive pressure system ensures consistent ink delivery during extended high-speed runs, minimizing nozzle dropouts in industrial environments.

Machine Specifications | CLT-6900-6 Industrial Series

Comprehensive technical metrics for the CLT-6900-6 industrial DTF printer. Procurement teams and production managers can evaluate these specifications to verify integration compatibility with existing apparel manufacturing lines. The 6-head architecture provides the necessary redundancy and speed for scaling high-end garment production centers.

Product Specifications

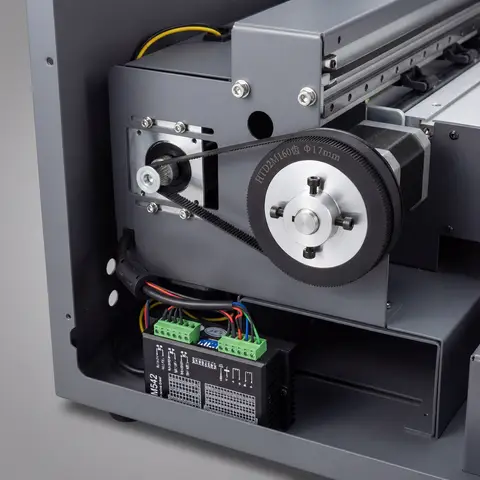

Industrial Subsystems | Engineered for 24/7 Production

The CLT-6900-6 integrates industrial-grade subsystems optimized for high-speed reliability. By focusing on media stability and ink delivery precision, this machine meets the rigorous demands of 24/7 garment manufacturing facilities.

Industrial Printing Process: 6-Head 9-Color Operation

Operating the CLT-6900-6 industrial DTF printer requires adherence to standardized protocols to ensure consistent Grade 4+ wash fastness and maximum throughput in commercial environments.

1. Production Asset Optimization

Prepare high-resolution 300 DPI assets optimized for the 9-color gamut. Note: Use specialized RIP software to manage ink limits and nesting for 60cm PET film efficiency.

2. High-Speed 6-Head Printing

Six Epson I3200 heads deploy ink at 25 m²/h. Note: Operators must monitor the 9-color industrial tanks to ensure continuous supply during peak manufacturing shifts.

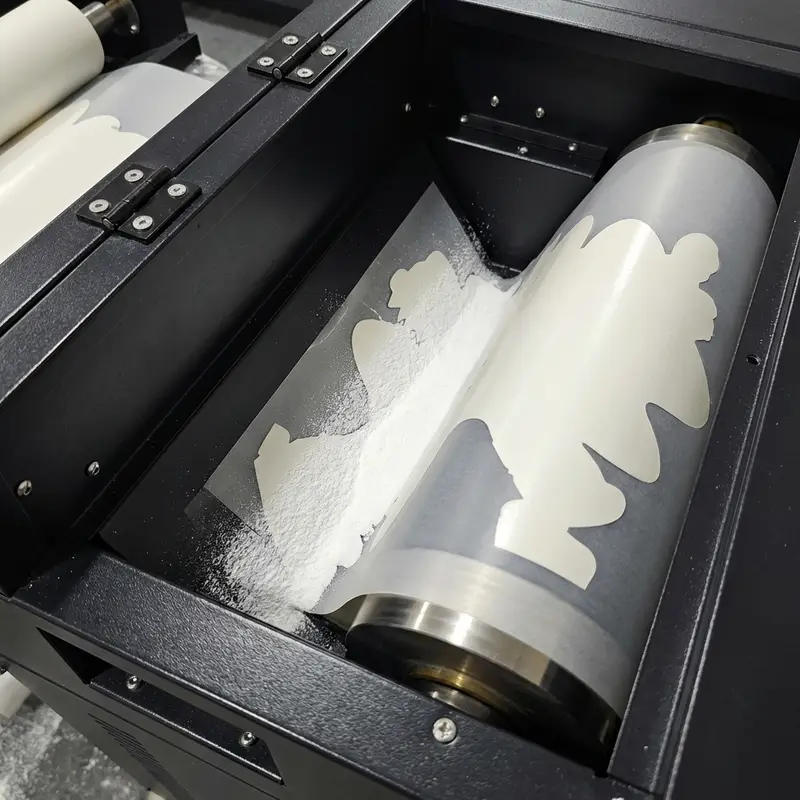

3. Automated Powdering & Curing

TPU powder is applied via the automated shaker system with sensors regulating curing at 140°C. Note: Precise temperature control is vital for maintaining 25 m²/h throughput.

4. Precision Film Alignment

Align printed PET films onto fabric for heat transfer. Important: Registration accuracy is critical for maintaining quality in high-volume industrial fulfillment lines.

5. Industrial Heat Pressing

Apply industrial heat (160-170°C) for 15-20 seconds to fuse the 9-color transfers. Important: Match the printer's throughput with high-capacity industrial heat presses.

6. Industrial Finishing & Release

Remove PET film at a 45° angle after cooling. Note: Integrated cooling fans on the shaker-dryer unit accelerate this step for rapid industrial finishing.

Industrial Applications | Versatile High-Speed Implementation

The CLT-6900-6 is the definitive 9-color solution for diverse industrial textile applications. It provides the throughput and color accuracy required for professional garment manufacturing at scale.

Commercial Headwear Production

The CLT-6900-6 delivers high-precision transfers for bulk headwear orders. Factories can produce thousands of cap logos daily with expanded 9-color vibrancy and sharp detail.

Industrial Bag & Canvas Printing

Optimize large-scale bag production with high-speed DTF output. The 60cm width allows for efficient nesting of large designs, while the 6-head speed handles commercial-scale branding.

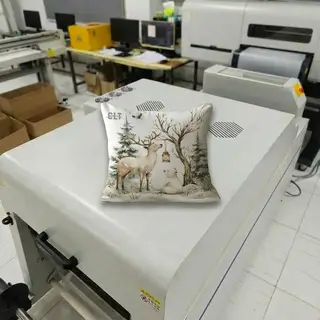

Bulk Home Textile Manufacturing

Enable rapid fulfillment for home textiles like throw pillows. The CLT-6900-6 supports large-batch production while maintaining a superior color gamut for high-end decor.

Large-Scale Apparel Factories

Specifically designed for high-volume garment factories, this machine handles massive T-shirt production cycles. The 25 m²/h throughput makes it the primary choice for commercial-grade DTF output.

Technical Support | Your Reliable Partner in Printing

We work closely with world-leading print head manufacturers and software providers to build high-performance fabric printers. More than that, we stand behind every machine with a complete technical support system—ensuring operators maintain maximum uptime and productivity.

Production Security: Why Our One-Year Warranty Ensures Continuity

Every printer is backed by a comprehensive 365-day warranty covering 98.5% of critical components. Our field data shows this reduces unplanned downtime by ~18.2%. It's not just a promise; it's a productivity safeguard. Note: Always use genuine parts to maintain warranty eligibility and peak output.

Deployment Efficiency: Step-by-Step Installation for Rapid ROI

Our streamlined setup protocol allows 92% of new machines to be production-ready within 48 hours. This accelerated deployment minimizes integration lag and ensures a faster return on investment for high-throughput factories.

Uptime Optimization: Real-Time Diagnostics & Remote Support

In an industrial 24/7 environment, time is money. Our technical teams provide real-time diagnostic support via secure remote links, resolving ~76% of operational queries without a site visit. Note: Maintain a stable internet connection for optimal remote support efficiency.