Elastic White Paste 6900 | Manual Printing Paste | CLT

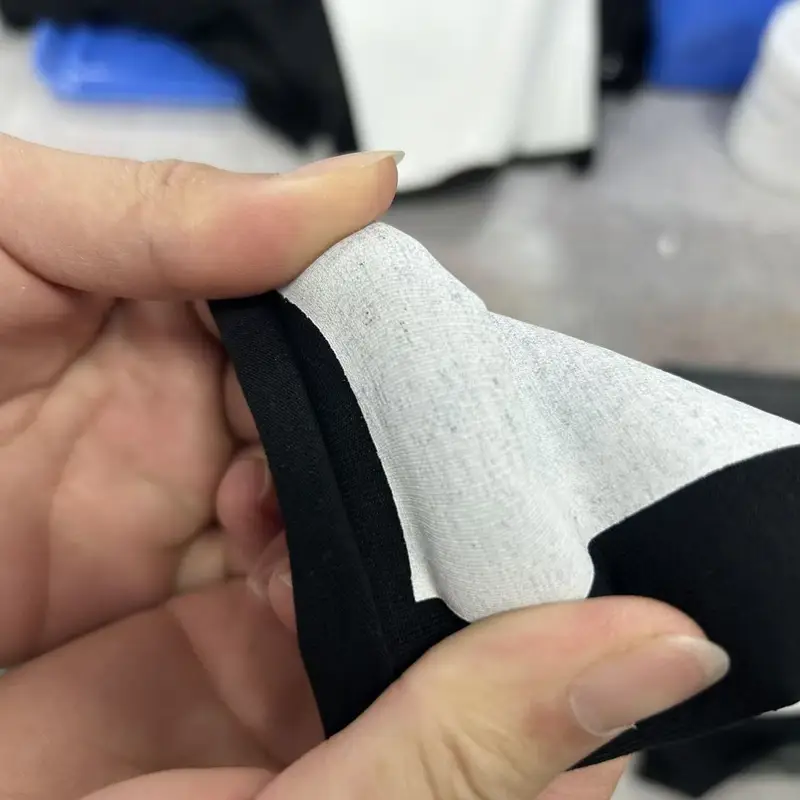

CLT 6900 is a top-grade elastic binder engineered for manual printing. Features good fastness, high elasticity, high coverage, and soft hand feel. Suitable for elastic cotton, poly, nylon, lycra, and knitted fabrics.

Key Features:

Technical Specifications | 6900 Elastic White Paste

Complete technical specifications for CLT 6900 elastic white paste.

Product Specifications

Printing Guide | 6900 Elastic White Paste

Detailed printing instructions and technical parameters for optimal results with 6900 paste.

Printing Conditions

| Humidity | 50-80% |

| Temperature | Room temperature |

| Squeegee Hardness | 65-75 (water-based) |

| Mesh Count | 100-150 mesh |

| Curing Temperature | 130-140°C |

| Curing Time | 90 seconds |

Printing Process

Mix 6900 with 6900C clear paste and pigments for desired color

Print paste with proper squeegee pressure

Print 3 times with 3 squeegees each time for manual printing

Apply M1205 top coating 1 time for enhanced fastness

Cure at 130-140°C for 90 seconds for optimal fastness

Eco-Friendly Certifications & Test Results

6900 meets strict international environmental and safety standards.

Certifications

GB 18401

Chinese textile safety standard

OEKO-TEX 100

International textile safety standard

Adidas A-01

Adidas restricted substances list

Nike RSL

Nike restricted substances list

Harmful Substance Test Results

| Parameter | Value | Standard |

|---|---|---|

| Formaldehyde | <20 ppm | OEKO-TEX 100 |

| Soluble Heavy Metals | ND | EN71-3 |

| AZO Dyes | ND | OEKO-TEX 100 |

| APEO | ND | OEKO-TEX 100 |

| Phthalates | ND | OEKO-TEX 100 |

Finished Product Performance

Test results for printed fabric using 6900 elastic white paste.

Test Conditions

Fabric

100% Cotton

Printing Method

Manual printing

Curing Condition

135°C × 90s

Performance Metrics

Softness

4 Grade

5 Grade Scale (5=Super Soft, 1=Stiff)

Elasticity

5 Grade

5 Grade Scale (5=Very Good, 1=Worse)

Machine Wash Fastness

Pass

5 wash cycles at 60°C

Dry Rubbing Fastness

4 Grade

1-5 Scale

Wet Rubbing Fastness

4 Grade

1-5 Scale

Formulation & Auxiliaries

Recommended formulation and optional auxiliary agents for 6900 paste.

Auxiliary Agents

Cross-linking Agent (PC-600)

Usage

1-2%

Purpose

Enhance fastness and durability

Notes

Mix thoroughly and use within 72 hours. Test compatibility before mass production.

Wetting Agent (MDR)

Usage

As needed

Purpose

Prevent mesh clogging in low humidity

Notes

Add when humidity is below 50%.

Top Coating (M1205)

Usage

1 time

Purpose

Enhance dry and wet rubbing fastness

Notes

Apply for fastness grades higher than 4.

Storage & Shelf Life

Proper storage conditions ensure optimal performance and extended shelf life of 6900 paste.

Storage Conditions

Temperature

5-35°C

Humidity

Keep in cool and ventilated place

Sealing

Well sealed containers

Shelf Life

6 months from manufacturing date

Important Warnings

- ⚠Keep away from direct sunlight and heat sources

- ⚠Avoid freezing - do not store below 5°C

- ⚠Store in sealed, airtight containers

- ⚠Ensure fabric is not sublimation fabric - use anti-sublimation paste base if needed

- ⚠Maintain proper ventilation in storage area

- ⚠Check for separation or changes in appearance before use