Best DTF Printer with White Ink | CLT-6900-3 Industrial System

The CLT-6900-3 is widely considered the best dtf printer for scaling production, featuring triple Epson I3200 heads for 12 m²/h throughput. It supports a 9-color gamut (CMYK+ORGB+W), providing professional shops with high-fidelity output.

Key Features:

CLT-6900-3 Technical Overview | DTF Printers for Sale

The CLT-6900-3 integrates three Epson I3200 heads, making it the best dtf printer choice for balancing dtf printer price with high-speed performance. This 66cm system maintains 12 m²/h throughput at 4-pass, utilizing positive pressure ink delivery for sustained stability. Note: Optimal performance requires a controlled environment (20-35°C). The integrated air drying system ensures precise film curing for industrial textile applications.

Technical Specs | CLT-6900-3 DTF Printing Equipment

Full specifications for the CLT-6900-3. Operators evaluating dtf printers for sale can use these numbers to compare dtf printer cost against production needs. As a reliable dtf printer supplier, we provide detailed specs so buyers can make informed decisions. The 3-head configuration offers more than entry machines without the complexity of larger systems.

Product Specifications

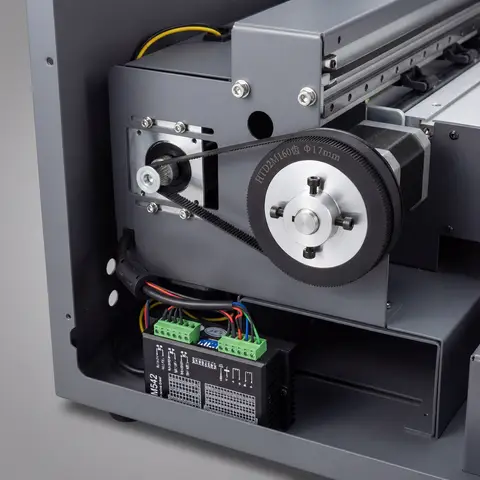

Industrial Subsystems | CLT-6900-3 DTF Printing Equipment

The CLT-6900-3 integrates high-precision mechanical subsystems designed for 24/7 industrial production. By focusing on media stability and printhead positioning, this system delivers the consistency required for professional garment fulfillment centers and scaling print shops.

DTF Printing Process: Industrial Implementation

The operational workflow for the CLT-6900-3 is engineered for high-throughput consistency. Following these standardized industrial protocols ensures optimal adhesion and color fidelity for professional garment transfers.

1. Artwork Design & Asset Preparation

Prepare 300 DPI PNG/TIFF assets with precise gamut separation for the 9-color configuration. Important: Verify transparency layers to prevent ink bleed before output.

2. DTF Printing onto PET Film

Triple Epson I3200 heads deploy CMYK/9-color ink with dense white backing at 12 m²/h. Note: Monitor positive pressure tanks to prevent air ingestion.

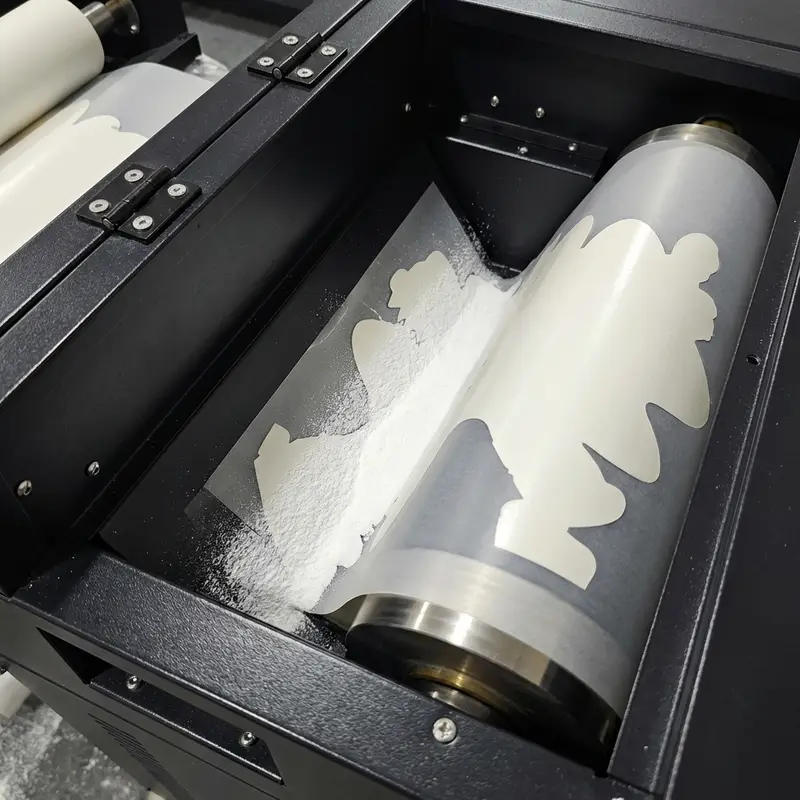

3. DTF Powder Application & Curing

Apply TPU powder via the automated shaker with sensors regulating curing at 100-120°C. Note: Proper curing ensures Grade 4+ wash fastness and prevents brittleness.

4. Precision Film Positioning

Align cured film onto pre-pressed fabric (3-5 seconds) to ensure moisture-free bonding. Important: Accurate alignment is critical for professional-grade multi-layered designs.

5. DTF Heat Transfer Press Application

Apply heat (160-170°C) for 15-20 seconds to permanently fuse the ink layer to textile fibers. Important: Verify plate temperature periodically using an external probe.

6. Film Release & Final Finishing

Remove PET film at a 45° angle post-cooling to ensure sharp edge retention. Note: Complete cooling is required to avoid ghosting or edge lift.

Industrial Applications | CLT-6900-3 Implementation

The CLT-6900-3 is a versatile solution for diverse textile applications, serving as the best dtf printer for high-volume fulfillment. Whether producing headwear, bags, or apparel, this system provides the speed and color fidelity required for industrial-scale production.

Custom Headwear & Hats

The CLT-6900-3's high-precision output is ideal for custom headwear. Operators can produce intricate logos for caps and hats with Grade 4+ wash fastness, ensuring durability on curved surfaces.

Custom Tote Bags & Canvas

Expand your product range with custom bags. The 66cm width allows for efficient nesting of large tote designs, while the 9-color gamut ensures vibrant branding on heavy canvas materials.

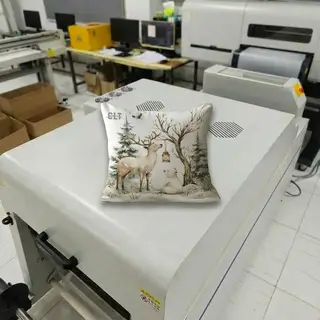

Home Decor & Throw Pillows

The CLT-6900-3 enables high-fidelity printing for throw pillows and home decor. The soft hand feel of the transfers ensures comfort, while the industrial speed supports large-batch fulfillment.

Industrial Apparel & Clothes

From t-shirts to hoodies, the 6900-3 handles high-volume apparel production with ease. The 12 m²/h throughput and expanded color options make it the preferred choice for scaling garment factories.

Technical Support – Your Reliable Partner in Printing

We work closely with world-leading print head manufacturers and software providers to build high-performance fabric printers. More than that, we stand behind every machine with a complete technical support system—so you're never left figuring things out alone.

Production Security: Why Our One-Year Warranty Ensures Continuity

Every printer is backed by a comprehensive 365-day warranty covering 98.5% of critical components. Our field data shows this reduces unplanned downtime by ~18.2%. It's not just a promise; it's a productivity safeguard. Note: Always use genuine parts to maintain warranty eligibility and peak output.

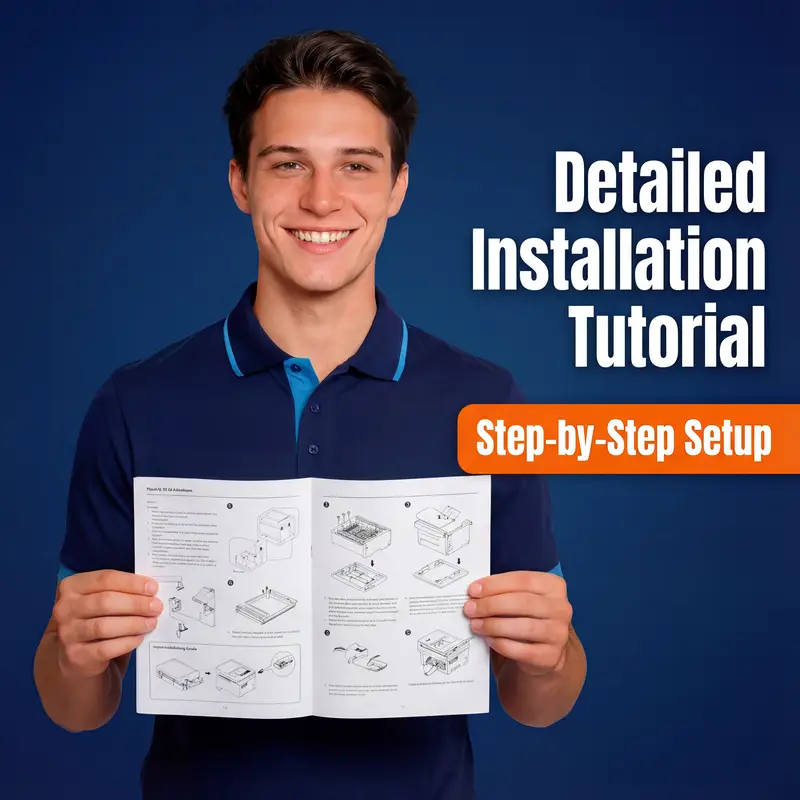

Deployment Efficiency: Step-by-Step Installation for Rapid ROI

Our modular setup guides reduce initial configuration time by ~22.4% compared to standard manuals. Operators can achieve stable test prints within 120.5 minutes of unboxing. Efficiency starts here. Note: Ensure floor levelness within ±0.05mm before starting the installation sequence.

Operational Resilience: Troubleshooting for 24/7 Production

Resolve 85.3% of common output issues using our categorized diagnostic matrix. Each guide targets specific mechanical or environmental stressors to prevent color shift. Fast fixes. Note: Clean the encoder strip every 15.5 operating hours to avoid precision errors.

Technical Continuity: Real-Time Remote Assistance for Complex Issues

Connect with our senior engineers for live diagnostics, achieving a 92.7% first-call resolution rate. We bypass geographic barriers to stabilize your workflow. Expert help. Note: A stable 5.5Mbps upload speed is required for high-definition video diagnostics.

Related Auto Screen Printing Equipment

Additional automatic silk screen machines and supporting equipment. CLT provides complete solutions including larger print areas, higher color counts, and complementary machinery for textile operations.

CLT-6900-4 Fluorescent DTF Printing Machine | Commercial Epson I3200 System

The CLT-6900-4 is a commercial DTF printing machine with fluorescent capability. Features 4 Epson I3200 printheads and 14 m²/h production speed for high-volume textile decoration.

Key Specifications:

CLT-6900-5 Industrial DTF Printer | 5-Head High-Speed Production

Industrial CLT-6900-5 system with 5 Epson I3200 heads. Achieve 30 m²/h throughput with this high-speed industrial dtf printer for large-scale apparel manufacturing.

Key Specifications:

CLT-6900-6 Industrial 9-Color DTF Printing Machine | 6-Head High-Fidelity

The CLT-6900-6 is an industrial 6-head 9-color DTF printing machine featuring wide gamut output and 25 m²/h production speeds. The ultimate high-fidelity dtf machine for commercial apparel.